Flowable Fill

Flowable Fill is a self- leveling, self compacted, low strength cementious material used primarily for backfill in place of compacted soils

Because of the product’s self leveling consistency, placing in lifts, tampering or compacting is not required. Flowable fill’s pix of Portland cement, fly ash or slag and sand can be designed to provide strengths ranging from 50 psi (7600 psf) to be over 1000 psi.

Chemical admixtures may also be used in flowable fill to modify performance properties of strength, flow, set and permeability. In addition, stable air generators can be used to improve flexibility, lower densities/ unit weights, reduce shrinkage, bleed water and subsidence, and control strength development in applications where future excavation is required.

| Benefits | Where is it used? | Order Types |

|---|---|---|

|

Backfill

Other Uses

|

|

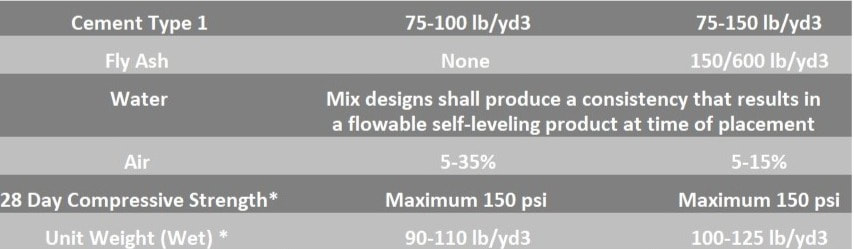

Flowable Fill Mix Designs

The chart below includes suggested mix guides for excavatable and non excavatable flowable fill

| Excavatable | Non-Excavatable |

|---|

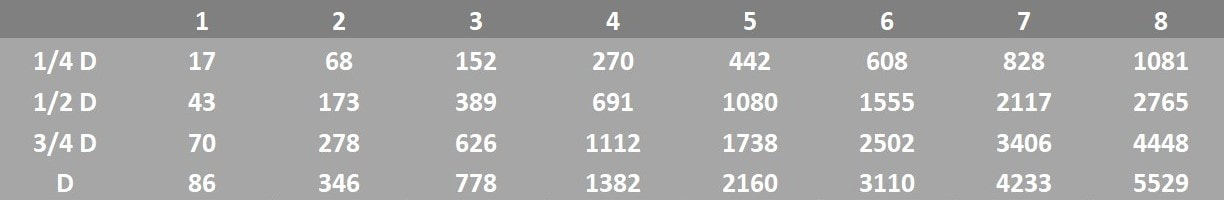

Buoyancy Force

(Pounds Per Linear Feet of Culvert)

Pipe Diameter (Ft)

| Depth of Fill |  |

|---|